Exclusive Interview with Jim Fuller of Rifle Dynamics: Kalashnikov DIY Tips and a First Look at their Production AKs

Exclusive Interview with Jim Fuller of Rifle Dynamics: Kalashnikov DIY Tips and a First Look at their Production AKs

Kelly and I recently had the unique opportunity to visit the talented crew of Rifle Dynamics in Las Vegas, NV for a behind the scenes look at what they’re all about. It was great to meet such an awesome group of people running the show at a solid American company.

This article is packed full of awesome information on the AK platform, including an interview with owner Jim Fuller and his no-nonsense explanation of 922R Compliance, what to look for when purchasing an off-the-shelf AK, DIY tips on how to keep your AK in top shape and an exclusive first look at the first Rifle Dynamics Production AKs.

Rifle Dynamics

Learning all about how Rifle Dynamics got it’s start, was great to hear from Jim himself and what they’re bringing to the industry. Purpose built fighting rifles that you can stake your life on is what they do best. Their credo, “these must work under the most extreme conditions,” lives up to the quality they produce.

Learning all about how Rifle Dynamics got it’s start, was great to hear from Jim himself and what they’re bringing to the industry. Purpose built fighting rifles that you can stake your life on is what they do best. Their credo, “these must work under the most extreme conditions,” lives up to the quality they produce.

While being well known in the industry for manufacturing combloc (communist bloc) weapons, specifically the Kalashnikov, Rifle Dynamics got its start in 2007 after Jim realized that there weren’t many armorers or gunsmiths that understood the AK platform and the true needs of the fighting man. What started as a torture test and a hobby of learning about the platform, turned into all that Rifle Dynamics is today.

Something we noticed when touring Rifle Dynamics, was just how passionate everyone was about their job and wanting to provide the best craftsmanship possible to their end user. It’s always inspiring when you get to talk to the people behind the scenes and learn all about what makes them tick.

The Kalash

Whether you call it an AK, Kalashnikov, or Kalash, the timeless combloc firearm was one of the first assault rifles manufactured. AKs are well known for their reliability, ease of use and lower price point. That last point about price can be misleading, as not all AKs are created equal. Jim gets into that below in a video on what to look for when purchasing an AK, it’s a must watch for anyone considering an AK purchase.

The Avtomat Kalashnikova (AK) was the brainchild of weapon designer Mikhail Kalashnikov in 1946, when he entered the codenamed AK-1 in a competition started by the Soviet Army to find an assault rifle capable of firing the new shortened version of the 7.62x41mm cartridge, known as the M1943 (7.62x39mm). It’s also been said that the reason for the competition was to find a competitor to the Sturmgeweher 44 (StG44) that the Germans effectively employed against the Soviets in WWII. The StG44 fired the 7.92x33mm Kurz round, a shortened version of the 7.92x57mm Mauser round.

The codenamed AK-2 is what would become the AK-47, after a design improvement was suggested by Kalashnikov’s assistant in 1947. While not officially adopted by the Soviet Army until 1949, the Kalashnikov production was certainly not without faults. While starting the production with stamped sheet metal receivers (Type 1), there were problems with warping that caused high rejection rates.

A machined (milled) receiver was substituted and production continued, albeit very slowly. These steel milled receivers are referred to as Type 2 (1959 – 1953/54 and Type 3 receivers (1953/54 – 1959). In 1959 the original Type 1 warping problem was solved and a stamped sheet metal receiver was re-introduced as the Type 4 or AKM (M meaning modernized). The AKM is what’s traditionally encountered today and what most AK variants are based on, though still incorrectly called AK-47s instead of AKMs.

In 1974 the Soviets began fielding a new design that utilized the smaller 5.45x39mm cartridge, which they dubbed the AK-74. One thing you have to give to the Soviets, is that their naming convention is pretty straight forward! It’s been said that the utilization of a smaller round came out of the US adoption of the 5.56mm, although that was ten years earlier. The 5.45 did significantly reduce the weight of the 7.62x39mm round to about half.

1979 is when the AK-74 first saw service with Soviet forces in the Afghanistan conflict and is still in production today, along with the AKM. These two firearms share around a 50% parts commonality. Just like the history of the M-16, the AK isn’t without problems, but the history of the AK platform is a little easier on the end-user than the M-16 and it’s early malfunctions.

The AK was originally designed to stand up to the wet, muddy and freezing conditions in Russia and is still well know for these characteristics today. As mentioned earlier, all AKs are not created equal. Here’s Jim with what to look for in your next purchase.

What To Look For When Purchasing AKs

DIY Tips

As you can see from Jim’s video below, there are quite a few things the DIYer can tackle with the AK platform, but the majority of improvements to the AK require access to machining. This is why taking the same approach to the AK that we took with the AR in our DIY AR-15 Build, isn’t feasible.

The AK requires jigs and machining that the average person doesn’t have access to, such as being able to properly dimple the receiver for strength or utilizing harder rivets vs. standard american aluminum rivets; working on the AK is definitely a tedious process. Don’t get me wrong, there’s certainly a lot of tedious work that goes into the AR as well, but you can build an AR from the ground up with just a few tools and a vice, not so with an AK.

Also, if something is out of spec on your AK it will never run right. It’s better to leave the more complicated processes to professionals, like the crew at Rifle Dynamics. This is why I left my Romanian SAR-1 with the crew at Rifle Dynamics for some work and can’t wait to report back on the modifications I’m having done. With the success of the Battle Comp 1.5 we permanently attached during our DIY AR-15 Build, one of the things I’m having done is getting a Battle Comp AKBC installed.

Call me a traditionalist, but I can’t bring myself to get rid of the wood stock and handguard you see in the photos here of what my SAR-1 looked like when I left it with Rifle Dynamics. Still to this day it’s some of the nicest wood I’ve seen on an AK. Jim mentioned how well the SAR-1 was built by the Romanians and a great base gun to start with. I was particularly impressed with the fact that it had the correct headspacing, as a lot of the off-the-shelf AKs don’t.

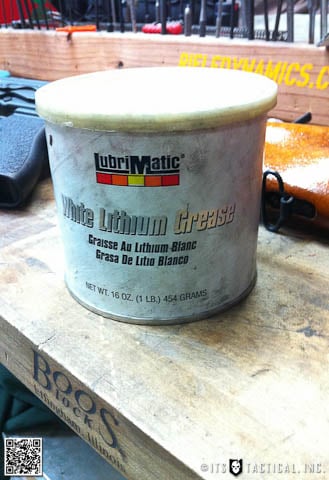

One last tip request came to us via Facebook, where Kurt asked what the Rifle Dynamics preferred to use for lubrication on AKs. Jim’s answer was White Lithium Grease. Check out the photos at the bottom of this article for the point on the AK Bolt and Bolt Carrier that Jim recommends lubing at. By placing the grease at these key locations, it will lube the AK in the necessary spots as it’s charged a few times.

One last tip request came to us via Facebook, where Kurt asked what the Rifle Dynamics preferred to use for lubrication on AKs. Jim’s answer was White Lithium Grease. Check out the photos at the bottom of this article for the point on the AK Bolt and Bolt Carrier that Jim recommends lubing at. By placing the grease at these key locations, it will lube the AK in the necessary spots as it’s charged a few times.

If you’d like to learn more about what you can do with the AK platform at home, be sure to check out the Panteao Productions AK Armorer’s Bench DVD with Jim Fuller.

Rifle Dynamics Production AKs

In true Soviet style, Rifle Dynamics has kept things simple by offering four models of their new production rifles. The RD 700 series is chambered in 7.62x39mm, while the RD 500 series is chambered in 5.45x39mm. Each series has the option of a triangle sidefolder stock or a Magpul CTR with the RD AKM-4 stock adapter.

- RD 501 – 5.45×39 w/ Triangle Sidefolder

- RD 502 – 5.45×39 w/ Magpul CTR

- RD 701 – 7.62×39 w/ Triangle Sidefolder

- RD 702 – 7.62×39 w/ Magpul CTR

Built from stock Saiga IZ 132’s (7.62) and IZ 240’s (5.45), Rifle Dynamics strips them down to bare receivers, pulls the barrels and starts the rebuild process. The Saiga platform is utilized for the quality of the Russian cold hammer forged chrome-lined barrels and properly heat-treated receivers.

All models feature custom front end work, such as the barrel being cut, crowned, threaded and pinned to an overall length (OAL) of 16.25″ to include the compensator. The Battle Comp AKBC is included on the 700 Series and the Battle Comp 2.0 on the 500 Series.

Other modifications include:

- Bolton Gen 2 Gas Block

- Ultimak Scope Rail

- K-Var Lower Handguard

- US Palm Pistol Grip

- US Trigger Group

- Krebs Retainer Plate

- Fuller Rear Sight Mod

- Sandblasting and Parkerizing with Norrells Moly Resin Finish in your choice of Black or FDE

A few other attention to detail items that Rifle Dynamics includes and are well known for, are fitting the trigger group, fitting the bolt carrier/rails, re-headspacing, polishing/correcting angles on the bolt lugs and front trunnion for smooth locking and unlocking. They also dehorn the trigger guard, magazine release, safety and charging handle. Factory side rails are removed for less weight and a cleaner look, with all unused holes TIG welded and cleaned up.

You can see there’s a tremendous amount of work that Rifle Dynamics puts into each one of these new production rifles and as the video below shows, they shoot like a champ! Having personally fired the RD 501, I can’t say enough good things about what the crew at Rifle Dynamics have accomplished out of the AK platform! Reach out to Rifle Dynamics if you’re interested in their new production AKs, they’re going quick!

A new product from Rifle Dynamics, that’s just been announced, is their exclusive Battle Comp AKBC74. The new compensator will fit 24mm right hand thread on most 5.45 AKs equipped with a 24mm front sight base. There’s also a prototype being kicked around for 7.62 as well.

Out on the Range with Rifle Dynamics

Kelly and I really enjoyed the opportunity to run some guns out of Rifle Dynamics’ arsenal. We shot the production rifles, a few fully-auto AKs and Krinks, as well as the AES-10B and PKM. While I love shooting full-auto, I cringe every time I do at the cost of that wall of lead!

We’d like to thank Jim, Karen, Roger, Billy and the entire Rifle Dynamics crew for rolling out the red carpet and their incredible hospitality. We appreciate them taking the time out of their busy production schedule to meet with us. Hopefully we can return the favor next time they’re out this way in Texas.

I highly recommend the professional crew at Rifle Dynamics for your next AK project, check them out online and be sure to stop by and visit their Facebook page while you’re at it!

Discussion