Soft Body Armor

Soft Body Armor

Terminal Ballistic Information

For those of us who have used soft body armor, and for those in the market to make a purchase, the following is a must read. The information comes from subject matter expert Dr. Gary K. Roberts, LCDR, USNR.

Background and Qualifications

Dr. Roberts is currently on staff at Stanford University Medical Center, a large teaching hospital and Level I Trauma Center were he performs hospital dentistry and surgery. After completing his residency at Navy Hospital Oakland in 1989, Roberts studied at the Army Wound Ballistic Research Laboratory: Letterman Army Institute of Research while on active military duty, and became one of the first members of the International Wound Ballistic Association.

Currently Roberts has been tasked with performing military, law enforcement, and privately funded independent wound ballistic testing and analysis. Roberts remains a Navy Reserve Officer and has recently served on the Joint Service Wound Ballistic IPT, as well as being a consultant to the Joint FBI-USMC munitions testing program and the TSWG MURG program. Roberts is frequently asked to provide wound ballistic technical assistance to numerous U.S. and allied SOF units and organizations.

Roberts is also a technical advisor to the Association of Firearms and Toolmark Examiners, as well as to a variety of federal, state and municipal law enforcement agencies. He has been a sworn Reserve Police Officer in the San Francisco Bay Area, where he now he serves in an LE training role.

Dr. Roberts has given us permission here to further disseminate his criticisms of the National Institute of Justice (NIJ) armor testing. As you might know, the NIJ is the U.S. Department of Justice body that has been testing and developing body armor and performance standards for ballistic & stab resistance since the mid-1970s.

From Dr. Roberts…

NIJ body armor testing is flawed and does not adequately assess the protective qualities of soft body armor. These problems have been known for quite some time. For example, the U.S. Congress, Office of Technology Assessment (OTA), published “Police Body Armor Standards and Testing”, a two volume critique of NIJ armor testing 16 years ago:

U.S. Congress, Office of Technology Assessment, Police Body Armor Standards and Testing, Volume I, OTA-ISC-534 (Washington, DC: U.S. Government Printing Office, August 1992). http://www.wws.princeton.edu/cgi-bin/byteserv.prl/~ota/…1/1992/9229/9229.PDF

U.S. Congress, Office of Technology Assessment, Police Body Armor Standards and Testing, Volume II: Appendices, OTA-ISC-535 (Washington, DC: U.S. Government Printing Office, September 1992). http://www.wws.princeton.edu/cgi-bin/byteserv.prl/~ota/…1/1992/9230/9230.PDF

During that same time period, several other papers, highly critical of NIJ testing were also published:

Jason, A. Fackler, ML: “Body Armor Standards: A Review and Analysis.” Wound Ballistics Review, 1(1), Winter 1991.

Bachner, TE: “The ‘V50 Ballistic Limit: A Reliable Test for Body Armor.” Wound Ballistics Review, 1(4); pp 20-25, 1994.

MacPherson, D: “Projectile Dynamic Interactions and Associated Body Armor Effects.” Wound Ballistics Review, 1(4); pp 29-31, 1994.

MacPherson, D: Fincel, E; Miloskovich, N: “Body Armor Penetration Dynamics.” Wound Ballistics Review, 3(2); pp 16-24, 1997.

MacPherson, D: “A body Armor Penetration Rumor.” Wound Ballistics Review, 3(4); p 29, 1997.

Unfortunately, NIJ did not make substantial improvements in their methodology over the next decade…

Fast forward to late 2001 and early 2002 when NIJ was informed by several sources that Zylon was exhibiting early degradation and was at risk for penetration–NIJ’s initial response was to pretend there was no problem. Only after several vests were perforated and officers were killed and wounded did NIJ finally begin a S L O W investigation that ultimately led to Zylon’s decertification in the fall of 2005, some four years after the problem was first identified.

Although the Zylon problems are thankfully now behind us, there is another problematic issue that NIJ is also aware of, but has once again failed to address–the ongoing problems associated with polyethelene laminate soft armor, including:

- Contact shot failures

- Curling

- Delamination

- Stiffness

- Heat retention

- Material strength degradation in heat

- Compression set wrinkling

- Fiber migration

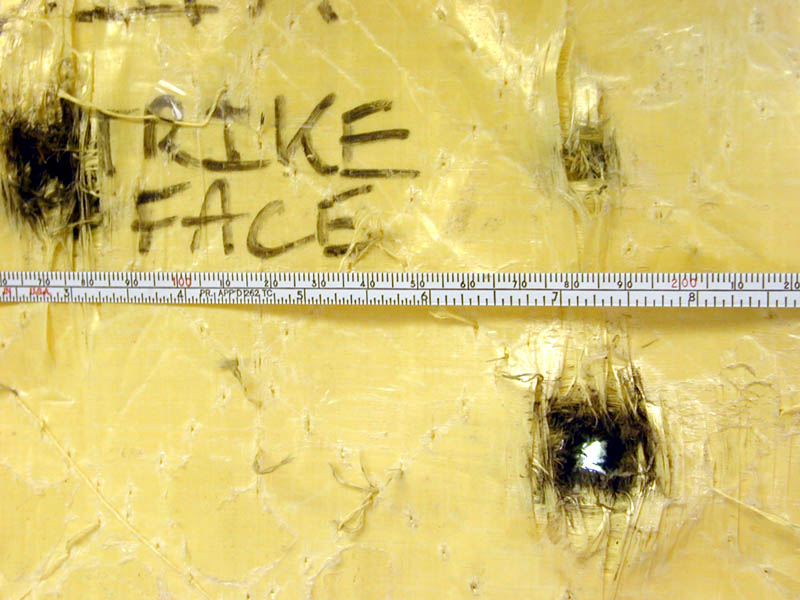

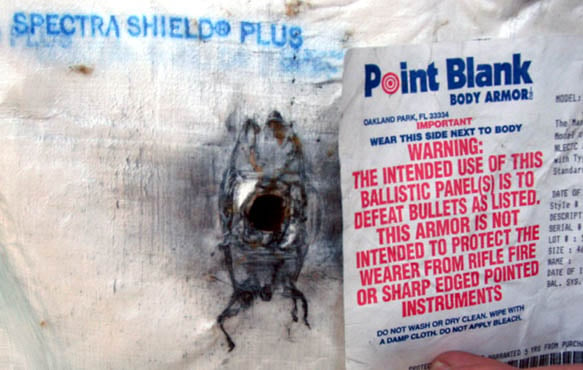

According to the last batch of data I saw reported from the FBI Uniform Crime Reports, approximately 1/3 of the incidents where officers were killed or wounded occurred at contact or near-contact distances. This seems like a fairly high potential for contact shots, yet NIJ inexplicably fails to test for this event. Contact shots can cause extensive damage to polyethelene laminate soft vest materials (Spectra Shield, Gold Flex, Dyneema, etc…) as noted in the photos below:

Contact shots appear to melt polyethelene laminate vest materials and result in large holes in the vests containing polyethelene laminate materials. Even when bullets are stopped, large holes are burned deeply into the polyethelene laminate materials resulting in the vests offering minimal protection against second shots to previously hit areas.

In contrast, 100% woven p-aramid vests can withstand contact shots with little damage, even in areas with multiple hits. For example, it took 8 contact shots of 9 mm FMJ, rapidly placed into the same location before this 11 year old Level II Kevlar vest finally allowed a full penetration, as noted in the photo below:

Beginning in the early 1990’s when the IWBA and the Congressional Office of Technology Assessment first publicly unveiled the serious errors and flaws with NIJ testing, it has been obvious that a new body armor test methodology was needed. The recent problems with Zylon and polyethelene laminate materials, along with the unethical behavior of many in the body armor industry has only reinforced the need for improved testing.

The current FBI Body Armor Test Protocol is a superbly conceived soft armor assessment that is the finest in existence, far surpassing the current NIJ body armor standards. This cutting-edge and innovative program is highly recommended; it is the new standard for body armor evaluation and will greatly contribute to improved officer safety. Any LE agency that knowingly chooses to purchase vests that don’t meet the FBI body armor test protocols is doing their officers a grave injustice…

For LE patrol use where the risk of contact shots is high, you want a vest tested and warranted to stop at least your own duty handgun round. The best soft armor choices remain vests that have passed either the FBI Body Armor Test Protocol, or any 100% all WOVEN p-aramid soft armor.

FBI Body Armor Test Protocol passing vests:

- Level IIIa DBT/CAT RVA3A fabricated with Kevlar XLT over backing layers of Kevlar XP

- Level IIIa DBT/CAT QVA3A-1 built using approximately a 50/50 mix of Twaron backed by Dyneema

- Level IIIa Pinnacle Armor level S2000-3A-01 made entirely of Twaron

100% Woven p-aramid vests:

- Level IIIa U.S. Armor Enforcer Classic

- Level IIIa Paraclete all Twaron armor

(Note–buyers should be wary, as there are laminated aramids, such as Gold Flex, that can be called 100% aramids, that are NOT the same as 100% WOVEN p-aramids.)

Remember, armor that passes the FBI Body Armor Test Protocol and 100% woven p-aramid vests may be a bit thicker, but they offer substantially more protection than many other vests on the market. Officer’s need to know that lighter, thinner, more expensive vests are NOT necessarily offering better protection. In addition, 100% woven p-aramid armor has demonstrated very long service lives.

We have tested numerous older Kevlar vests, including one that was 25 years old, a few that were 15-to-18 years old, and numerous vests in the 9-to-12 year range, that ALL continued to easily stop the threats they were rated for, including multiple contact shots from the same 9 mm and .44 Mag loads that perforated brand new polyethelene laminate vests.

Obviously, if you are NOT likely to get hit with a contact shot, for example military personnel on the battlefield, then contact shot performance is not as critical as for end-users, like U.S. LE patrol officers, who are likely to face contact shot threats.

Progressive LE agencies are beginning to require that all vests purchased for uniformed patrol MUST pass the FBI Body Armor Test Protocol. Vest purchasing contracts should always specify that each new vest come with TWO (2) vest carriers; in addition, going with one (1) wide side closure strap on each side rather than two (2) smaller ones is a good idea. Also, savvy agencies are inserting contractual requirements authorizing unannounced visits to the armor vendor’s manufacturing facility to observe how the raw armor materials are stored, and inspect the armor while it is being assembled.

Here is an example where the City of San Jose, CA required that vests they were seeking bids on passed the FBI Body Armor Test Protocol.

ITS would like to thank Dr. Roberts again for allowing us to post this valuable information, and we hope that you can pass it along to anyone you know in harm’s way.

Discussion