The Power of the Winch: A Guide to Off-Road Domination

The Power of the Winch: A Guide to Off-Road Domination

- The Power of the Winch: A Guide to Off-Road Domination

- The Power of the Winch: Learn the Basics of a Winch Line Pull

- The Power of the Winch: Advanced Techniques and Methods for Recovery

We’ve discussed a few important aspects of using and maintaining a winch in a previous article on Off-Road Recovery. However, with camping season fast approaching, we’ve decided it’s time to put together a series on how to select, set-up and maintain your winch. We’ll also be covering some conventional and unconventional uses of this fascinating, methodical and respectably dangerous piece of equipment. While we’ve touched on this before, there’s still a tremendous amount of information to cover. I’m eager to share my knowledge and experience with the community, so let’s get started.

Considerations for Winch Selection and Placement

Selecting the right piece of equipment in any endeavor can be a daunting task if you’re not well-informed. Even if you’ve done your homework, the miracle of modern marketing can help guide you down a rabbit hole that leaves you confused and a bit angry at the purchase you made a month ago. As we discover new information and research on unfamiliar topics, we find this sort of misinformation game directed explicitly at the consumer with a goal of making money. I get it. I love that we’re a capitalist country and frankly, I wouldn’t have it any other way. Companies have to make money to survive, but as consumers, we need to be well-informed or everyone suffers.

I’m not going to stand beside any particular product because it’s not fair to anyone here. I’ve been in many winch recoveries, from a simple stuck-in-the-mud pickup to putting vehicles back on four wheels after they ran out of talent. I’ve used dozens of winches, all with varying levels of success and power. Nearly all of my close friends own them and they’re all different brands, ratings and ages. Here’s the thing to remember, they all still work.

In fact, every winch I’ve personally seen fail has done so because of a lack of maintenance or experience. Sometimes, there’s nothing you can do about that. You don’t get to decide which materials the manufacturer used to obtain their IP67 ingress rating and you don’t control the weather.

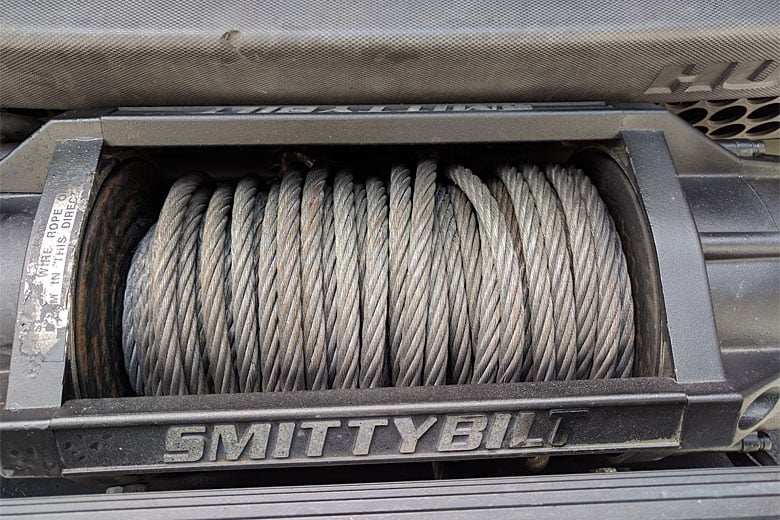

Here’s a bit of my personal experience. I bought a 10,000 lb.-rated Smittybilt X20 winch in June 2015. I’ve pulled about 30-35 times with it and have never had a problem, aside from one minor detail. The winch is waterproof, but the wireless controller isn’t. My first pull was a minibus in a torrential rain at the COTA track in Austin, TX. I got him out, but I lost my wireless function immediately. Fast forward a few months, when my good friend arrives with a used Jeep Wrangler and a Warn 9000 lb. winch that was installed 8 months prior. We couldn’t get it to work. We disassembled the electronics and the winch but never had any success. The level of corrosion throughout the vehicle led me to believe it was driven through some nasty surf and was never properly maintained.

What’s the point of those stories? I know that I can still run my winch like the day I bought it because I take care of it. That’s the most important piece of information I can give as far as selecting the right product. In fairness, I would stay away from some of the imported discount products on the Internet because they may not have decent quality control, if any at all. Even Tractor Supply gives you a considerable warranty on their “off-brand” winches.

When choosing a winch, there are many schools of thought. Obviously you’re going to want something with decent customer service and good reviews. The general line of thinking is to get something rated at 1.5 times the weight of your vehicle. For example, my truck has a curb weight of about 5,600 lbs. In my case, an 8,500 lb. winch would perform well for my application. I knew I was going to be adding accessories and beefing up some of my components, so I opted for the extra size and went to 10,000 lbs. I can’t remember what my justification was, but I believe there was a sale on the 10k X2O and that’s why I went there instead of the 9.5k. Bigger is not always better either. Dumping a huge winch into your frame rails, whether it fits or not, can cause you more problems on tough pulls than you may realize.

My friends and I built the mount on the front of my truck. We purchased a couple of prefabricated units and weren’t very happy with them. The problem was that the mounting plates wouldn’t hold up to 10,000 lbs of force. Instead, we used some 1/4” steel plates welded to some very heavy angle iron. We gusseted the weak areas and gave it a good coat of paint to prevent rust.

This is the kind of thing that’s often overlooked. My neighbor bought an aluminum aftermarket bumper for his Jeep. Mounting holes for his winch were included, but we spent some time scratching our heads on the rationale for doing that, considering the winch would quickly remove itself during any pull over a couple thousand pounds. Do people actually do this stuff? Installing winches on weak or ineffective materials? Yes, it happens more often than you’d think. Carefully consider where you’re installing the winch in your vehicle because it may become more of a liability than an asset if not done correctly.

The Great Debates and How to Pick Sides

We’ve discussed the synthetic vs. cable feud in a previous article so we won’t go into a lot of detail here. Personally I prefer cables, as they tend to last longer in this miserably hot climate. They’re more dangerous though. If you’re up to replacing a synthetic line every 2-3 years, then I think that’s definitely the way to go.

My next winch purchase will probably include a synthetic line. They’re lighter, safer and less detrimental to the continued function of a hand without leather gloves on. Cables are great and they’re really strong in comparison, but they weigh a lot and they splinter as they grow older. If you forget to return your winch gloves to the truck, you can still use a synthetic line without the risk of that blinding, white-hot pain of steel cable splinters and any diseases that may follow that injury. Yuck.

Terminating your winch line is another area with too many choices. Typically, winches include a standard gated winch/crane hook and these work fine for pretty much everything. Another popular option is a Bow Shackle, which runs around $8-$12 at a Tractor Supply, or online and is typically rated to more than your winch will pull. One item that’s really gained a lot of traction is the Factor 55 terminator blocks. I haven’t put much of a priority on getting one of these, but they’re really neat. They’re supposed to be stronger and safer than traditional hooks and shackles and they clean up very nicely. Rubber pads on the mounting positions allow the blocks to be pulled against the fairlead. There are a ton of options for terminating your winch. All of them offer some kind of benefit or drawback, but if you have a solid recovery strap kit then you shouldn’t have any problems.

Choosing a fairlead seems to be more difficult than it needs to be. If you’re performing the winch pulls properly, there’s no reason to be concerned. A high-quality roller fairlead will most likely perform well for the life of the vehicle. The drawback here is that there are more moving parts, more weight and those plastic inserts commonly used on the kits will break and render them less effective. Hawse-style fairleads are lighter with no moving parts and keep a low profile. Companies are even starting to customize the unused space with customer-specified text and graphics. Rollers are great if you’re on a budget. However, if you’re always posting your rig on social media or you really prefer the look and simplicity, then you should get a Hawse fairlead.

As for all of the wireless functions, gadgets and other state-of-the-art business, I leave that to your discretion. You don’t need any of those extra things for your winch. They function well all on their own without any modifications. Yes, you’ll save some space by not bringing a controller cable along and the vehicle will look cleaner and more appealing to your subscribers on YouTube, but it’s not necessary to the successful function of your winch. Think about your needs, as well as your budget and go from there.

Setting Up Your New Winch for First Use

The first thing to remember is to get the bolts good and tight. If you have to drill the holes yourself, there should be a template included by the manufacturer. If you don’t have a template or you’ve purchased a used winch, you may need to get creative with some cardboard and permanent markers. Once that’s handled, make sure all of your wires are hooked up correctly. There should be equal lengths of positive and negative battery cables. It’s important to get these cables hooked directly to the battery. It’s never a good idea to ground your winch to the frame or other body panels. There’s a massive amount of energy flowing between the winch and the battery. In situations like grounding the device to the frame, you can actually melt panels or terminals. Aside from that, electrical currents dramatically accelerate rust and corrosion so you’re not doing your vehicle any favors.

There’s a considerable debate around fusing your positive cable on your winch. Personally, I fuse everything coming off the battery. I also have a large fire extinguisher and seat belt cutter readily available at all times. The only exception I make here is that I don’t fuse my winch lines. During a winch pull, amperage draw can range from 400-500 amps and finding a fuse that can handle that kind of abuse is tricky. Based on the information out there, you would need something like a 600 amp fuse to be able to handle that kind of load without interrupting your pull.

To be safe, you’d need several backup fuses in the vehicle at all times because they’ll burn up before the line is in any meaningful danger. More importantly is to be conscious of your routing decisions so that you’re avoiding unnecessary chaffing and rubbing. Remember that washboard roads (or corrugations if you use the metric system) are extremely unforgiving on wearable components. Think proactively and you’ll be successful here.

So now that we’ve got all the accessories, mounting plates and wiring all sorted out, we need to pretension the winch before using it. It’s always safe to assume the winch left the factory without several thousand pounds of resistance on the cable spool. First you’ll pull the winch line all the way out until you reach the very end of the line. The cable or line will be connected to the spool with a nut or bolt. Typically there’s paint or another marking on the cable that shows the amount that needs to remain on the spool. For instance, our winch requires 8 full wraps of the cable before the maximum 10,000 lb. load can be applied.

The small bolt holds the line in place for a series of turns determined by the manufacturer. Using the Capstan principle (a mathematically complex principle that’s easy to understand when described in rudimentary terms) it can be determined how many wraps are needed to secure the cable to the spool. Typically, the bolt or nut holding the line has a relatively low shear tolerance. This means that if you try to pull from the bolt with the line completely extended, it will likely just break. The Capstan equation states that with about five wraps of cable at a coefficient of .6, only 1 kg of force is needed to hold about 200 tonnes in place. I’m not sure what that means for my truck, but I’m not trying to lift aircraft carriers either. Plus it makes me look really smart to use words like “coefficient.”

We covered this process in great detail on our recovery article so we won’t mess with it too much more here. I suggest heading over and giving the section on winching a run through to see if this is something you’re up for. Now let’s talk about something that makes me sound like a broken record. Don’t shock load your winch. I’ve asked several of the big brands and they all say the same thing. Winches aren’t designed to have tension applied with the vehicle. You need to use the winch controller to gain tension on the line and then use the clutch lever whenever possible. It’s faster and not as hard on the winch.

I understand that a lot of winch mounting solutions don’t give you that option. If you’re going to use this setup and feed the winch line out with the controller, let the thing cool down for a minute. Get your engine RPM’s up to get the alternator working on your battery in the meantime.

After your day of wheeling is up, get your friends together and fix your lines. I talked about the rat’s nest before and I maintain that winch lines should always look like they’ve never been used. Pretty doesn’t mean “pavement princess,” it means you know what you’re doing. I’m going to end every piece in this series with the following statement: The tow ball on any vehicle is never an acceptable recovery point. There are new videos coming out regularly with the effects of stupidity. I know you guys got it, but tell your friends too. Do you homework and assess your needs. You’re always welcome to post questions in the comments and I’ll get notifications as they come in. Feel free to drop some hate there too. I don’t mind a good debate.

Editor-in-Chief’s Note: Derek Gill has been a Plank Owner here at ITS from the beginning and has an extensive background in healthcare, pharmaceutical research and technical diving. He’s been certified in SCUBA since 2000 and diving technical/CCR since 2010. He speaks several languages including Russian and Spanish as well as several computer languages. These combined skills have opened the door to more creative ventures in Network Security and Physical Security consulting. Derek is a veteran of the US Navy and a former Navy Corpsman who worked alongside the US Marine Corps. His military nickname, “Witch Doctor,” has stuck with him ever since and it can now be found across many internet forums where he takes pride in trolling sensational zealots from multiple industries.

Discussion